PRODUCTS

Raw Material

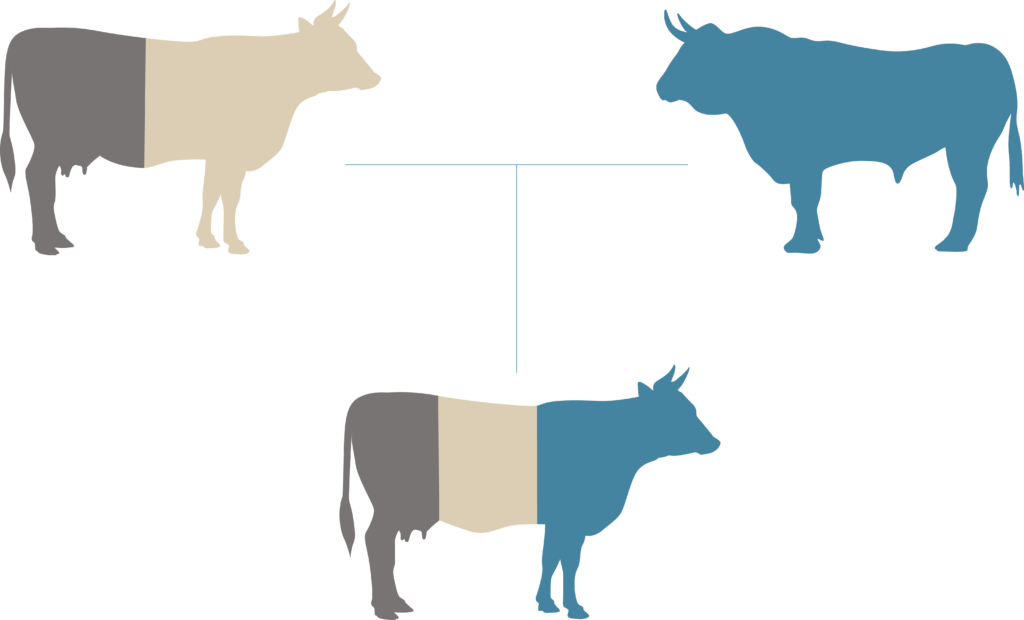

Our feedlots are mainly focused on animal welfare and sanitation, standing out the most on nutritional area. Right after weaning occurs, livestock breeding begins with our specialized feeding, depending on each animal growth curve.

A combination of genetics (potential grow) and nutrition (potential fuel) allows us to raise calves of 470 kgs/1036 lb. within their first year of life, accomplishing a valuable meat chain and obtaining the best from each phase.

BONE STRUCTURE

As bone structure development is the first to happen, it must be strong enough to support all tissues growing afterwards.

MUSCLE MASS

Muscle mass will then begin to demand on nutrients which are essentials to obtain the maximum benefit from the most valuable cuts of beef when deboning.

FINISHING

Finally, during the finishing process, deposition of fat occurs, which defines the marbling and tenderness of cuts. It is essential not to have excess of fat ,but to have it evenly distributed among the muscle fibers.

Production

The half cattles are kept into cold rooms until they enter to the production ones, where they are boned and made into cuts. They are individually vacuum packed or made in bulk, according to the needs of our customers.

Finally, they are labeled and stored in cold rooms until they are delivered to their destination. The time between deboning cuts and packaging them, is controlled to minimize the exposure of meat to the environment, and thus achieve outstanding quality.

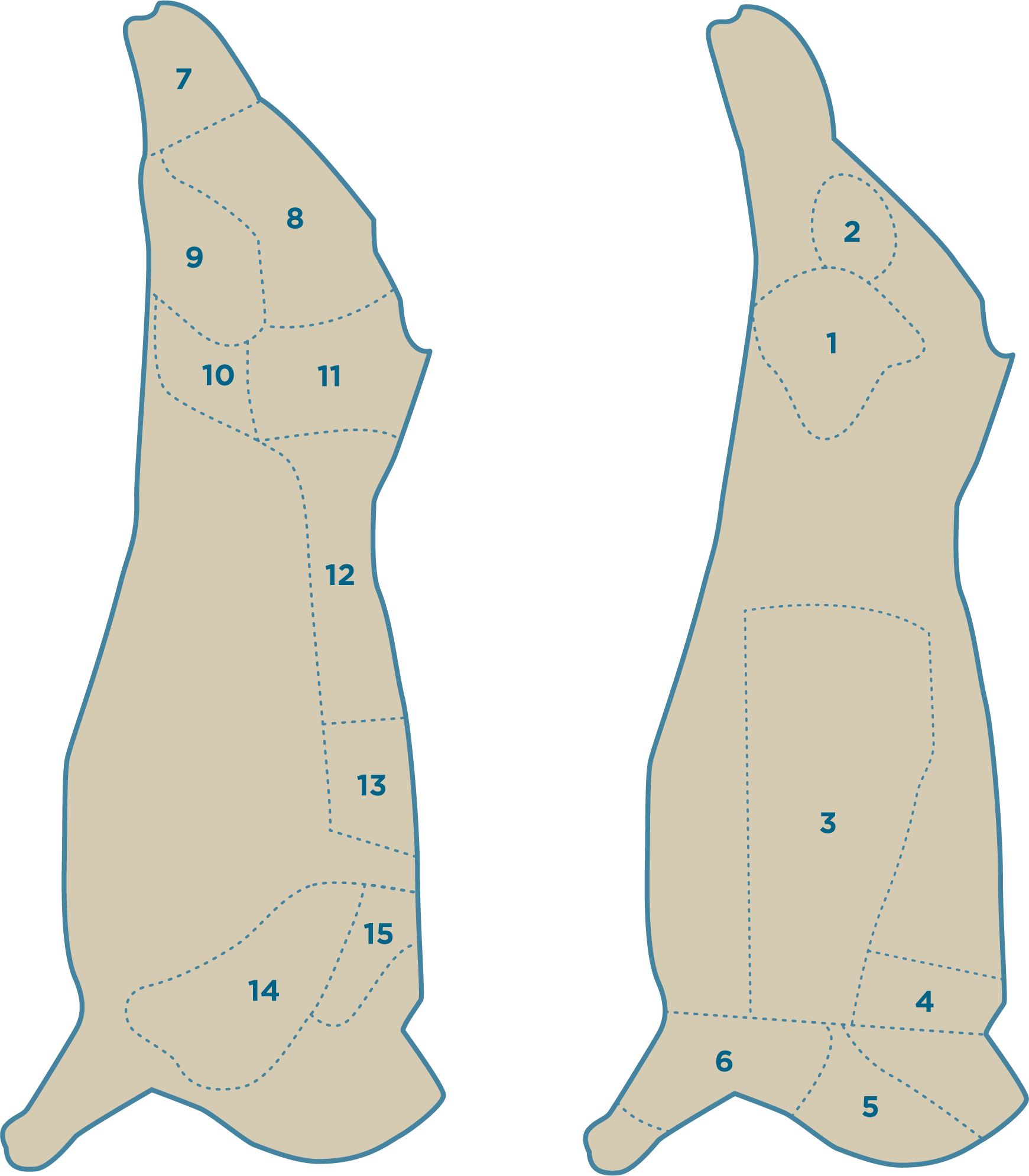

Cuts catalogue guide

01. Top Side

02. Heel Muscle with golden coin

03. Flank

04. Chuck Roll

05. Neck

06. Shin

07. Shank

08. Outside Flat

08b. Eyeround

09. Knuckle

10. Tail of Rump

11. Rump

11a. Cap of Rump

11b. Heart of Rump

12. Striploin

12b. Tenderlois

13. Cube Roll

14. Bolar Blade

14b. Chuck Tender

15. Oyester Blade

RES